The Technical parts division of GOTMAR LTD is specialized in the design and manufacture of products from thermoplastic polymers through injection moulding. The manufactured products have various industrial and household applications:

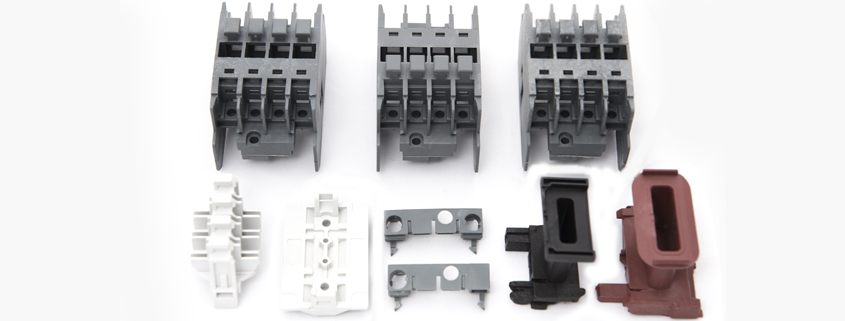

- Products for electrical application from glass-filled polymers

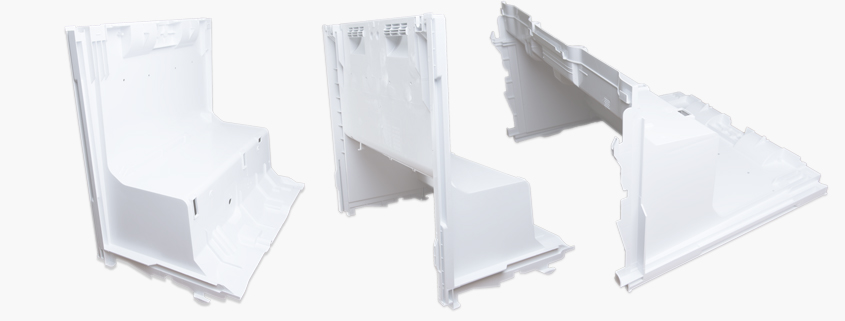

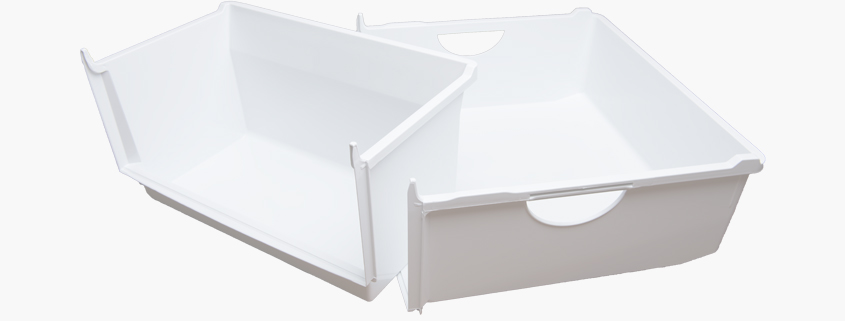

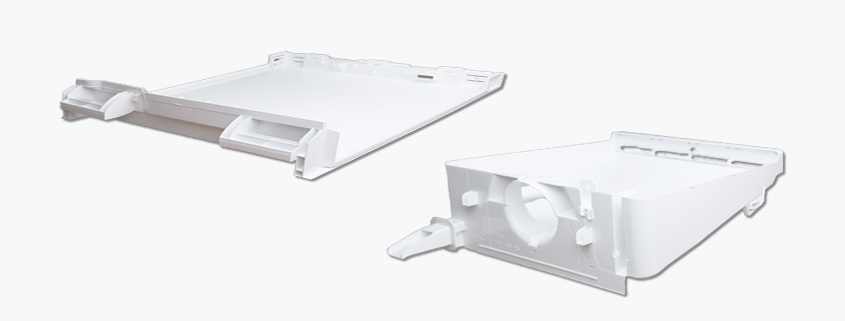

- Products for household appliances

- Products for the food industry

- Other products

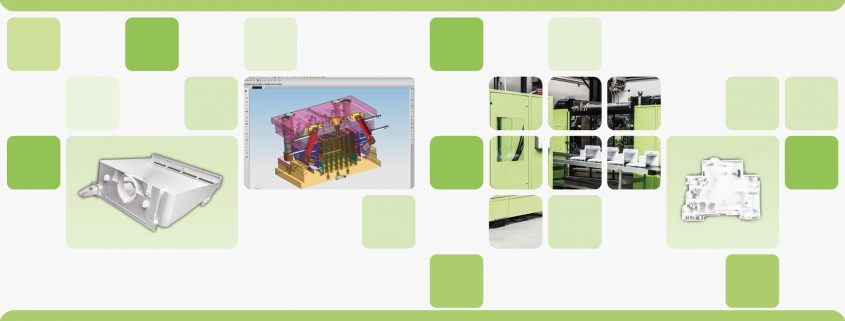

Know-how and technologies

Materials: The Technical parts division has extensive experience in the processing of a wide range of thermoplastic polymers – PS in different colours with specific application, PC and PA with various fillers and filling degree, other precision engineering polymers such as ROM, PBT, also polyolefins PP and PE. The distribution of materials to injection machines is centralized.

Machines: The Technical parts division has new energy efficient injection moulding machines in a wide range from 50 tons to 1500 tons. We have a special team for process setup and maintenance.

Molds: The Technical parts division designs, maintains and operates over 100 pcs injection moulds with different configuration and weight from 50 kg to 11000 kg. There is a very well equipped local zone for repair and maintenance, separate from the Tooling division.

Peripheral equipment: The Technical parts division has all the necessary systems for preparation of materials before moulding, devices for tempering moulds, precision gravimetric dosing units for dyes and secondary materials, systems for the separation of sprue and precise 3- and 4-axis robots.

Quality and control: The Technical parts Division has a separate laboratory for product testing that covers the whole range of linear-angular measurements and control of the appearance of the article by 3D measuring machine, high-speed microscopes, spectrophotometers and other electronic and mechanical devices and appliances guaranteeing high output quality.

Management and logistics: The administrative offices are in close proximity to the production and warehouse facilities and zones for ready products dispatch; this ensures quick and accurate services for our clients.

Introduced good practices and management methods for optimization and increase of know–how level: Projects under Lean and Kaizen, improved SMED system, strict ТРМ control, KPI visualization and measuring of the results from each sub-process, 5S tools for control over ever zone, prevention plans for maintenance, ongoing, internal and external training of personnel.

Technology:

- Injection moulding

- Co-injection

- Gas melt injection

- IML

- Overmoulding

За въпроси и повече информация, моля свържете се с нас на sales@gotmar.com